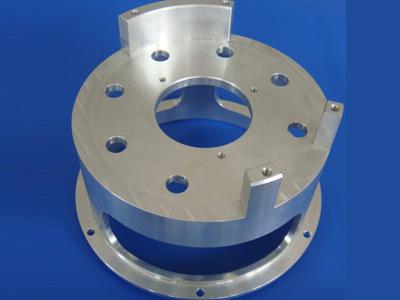

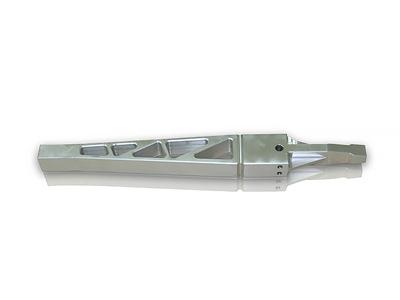

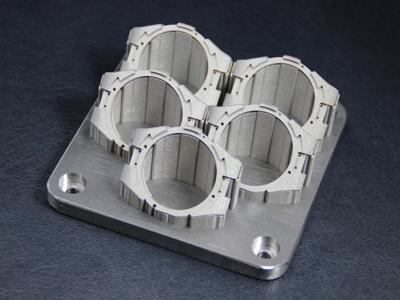

HONGYU is an experience manufacturer for automotive parts rapid prototyping, as we offer rapid prototyping services that allow our customers to evaluate the financial efficiency and practicality of their projects. Rapid prototypes are often considered the first sample of mass produced automobile components. Send us a blueprint or sample, and we will create your prototype through CNC precise machining centers.

We own and operate multiple CNC machining centers, ready to produce an array of automobile parts through 3 or 5 axis machining. Parts are produced using stainless steel, aluminum alloy, copper alloy, zinc alloy, and titanium alloy. With the help of agents all over the world, we have worked with international names, such as BMW, Mercedes Benz, Volkswagen, Tesla and more.

Automotive Rapid Prototyping Parts Applications:- Exterior Parts:

- Bumpers

- Grilles

- Headlights

- Spoilers

- Trunk Lids

- Chrome Trim

- Fenders

- Taillights

- Fog Lamps

- Mirror Housings

- Door Handles

- Interior Parts:

- Air Vents & Ducts

- Steering Wheels

- Dashboards

- Consoles

- Central Control Panels

- Arm Rests

- Door Panels

- Speaker Grilles

- Switch Plates

Because automobiles are constantly updated, there are a variety of designs, and each has to be tested for practicality and performance, which is where rapid prototyping comes in to turn a designer’s idea into reality, and assist the manufacturer in finding pros and cons quickly. This allows customers to optimize their design, as well as improve and simplify procedures to save their budgets.

The automobile industry requires parts that are highly accurate and high quality, with a tolerance required of up to ±0.015mm. Prototypes should be ready quickly, so that customers can evaluate its practicability quickly, and thus, quickly launch new designs onto the market. We are equipped with a variety of advanced equipment, including a 3/5 axis CNC machining center, to satisfy these requirements.

Samples of Our Automobile Rapid Prototyping Service Contact our technicians:“We are able to design prototypes and produce a variety of aviation part rapid prototypes in less time, and with your feed back, will design and send new samples- something traditional methods can’t do.”