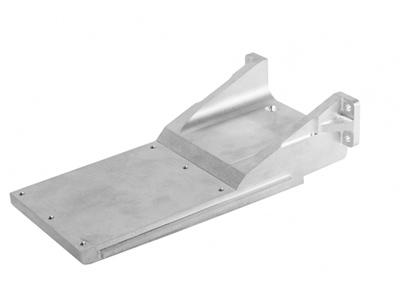

CNC rapid prototyping is cost effective solution for the production of aviation parts. It is the first step for testing a product’s practicality, as aircraft are built using a variety of high performance aluminum alloy parts, including the stocking system, bracket system and pod parts under the wings, and more. Our designers will offer you both the pros and cons of your new products through rapid prototyping, thus saving time and money in the manufacturing process

Applying CNC precise machining is one of the best options for rapid prototyping. HONGYU provides 5 axis CNC machine tools to do turning, milling, cutting, grinding and other works on a variety of materials for part production. For better quality, we apply rapid prototyping and Swiss-style CNC lathes for high performance aviation parts, with a tolerance of up to ±0.0001 inch. If you need manufacturing service, we offer small batch or large scale quantities in aerospace components.

We provide a variety of aviation parts, made from a variety of materials. Materials are listed below.- Stainless Steel

- Alloy Steel

- Copper

- Resin (ULTEM 9085 Resin,ULTEM 1010 Resin)

- Plastic (FDM Nylon 6, FDM Nylon 12, Digital ABS)

- Aerospace Prototyping Applications:

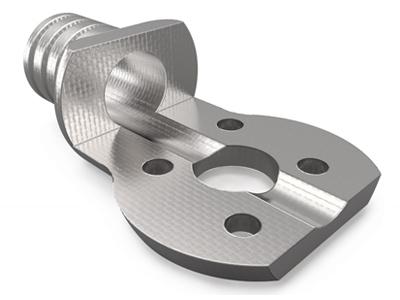

- Aerospace Couplings

- Seats

- Brakes

- Retainer Rings

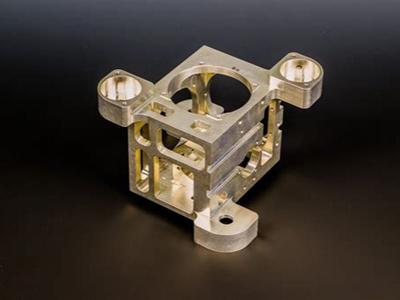

- Bearing housings

- Shafts

- Pins

- Fasteners

- Bushings and Spacers

- Electrical Parts

We apply 5 axis and 3 axis machining centers and vacuum casting to offer our customers the most time efficient and cost efficient processing services.

Our machining workshop has the resources for turn key components, producing those components requires extra services, such as heat treatment, electroplating, grinding and buffing.

Samples Contact our technicians:“We are able to design prototypes and produce a variety of aviation part rapid prototypes in less time, and with your feed back, will design and send new samples- something traditional methods can’t do.”