Hongyu uses high precision CNC machining to manufacture various molds for you. Even if you don’t have the design draft, just send us a product sample you want to produce. Depending on our years of experience, we can design three-dimensional drawing of the mold for you. We will start to produce the mold after you confirming the design draft.

We can manufacture various types of molds by CNC machining including plastic injection molding die, metal die casting die, gravity casting mold, etc. Our molds can be used to manufacture various products including car front and rear bumpers, dashboard, car front, headlight, home appliance, electronic communication product, 3C product, etc.

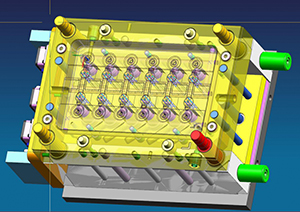

Mold Making- CNC machining.After we have received your design draft, we will check its feasibility firstly, then we start to make mold according to our customization flow. We will print CNC program file and check whether steel material, copper electrode, and mold base are OK. We use CNC machining center and precision grinding machine to manufacture mold.

We load the steel material, copper electrode, and mold base. We correct the coordinates, set the benchmark and input the program file on CNC machining center. We ensure each mold part and accessory has its unique number for easily tracking.

After the mold parts and accessories are produced, they will be sent to QC department to inspect key parameters like size. Then they will go to the EDM or wire-cutting process.

Mold Making-EDMAfter the QC department has confirmed the sizes of mold parts and accessories are correct. The copper electrodes will be sent to polishing workshop for surface finish before EDM process.

The EDM technicians check the copper mold parts, accessories, and electrodes. They create material form and EDM program file and ensure all details are OK. Then they put the steel material and mold base in the EDM machine and input the EDM program file, correct and set the benchmark. They will check the program file and EDM position once more before the EDM processing start.

During the EDM processing, the technicians will frequently check the EDM machine, fixture and workpieces to ensure the liquid is flowing, no carbon layer deposits on the surface of the workpiece, no undercut leaving, and the size of workpiece is correct, etc.

Mold Making-Wire EDMWire EDM is used to process the insert, inclined top, slider, groove and hole of the mold. All wire EDM processing will conform to the design draft and our quality control standards.

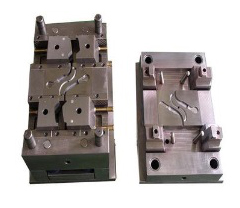

Mold assembly and fitting is the final process of mold making which shows a company’s process capability. We will professionally assemble various mold parts including front mold insert, post mold insert, slant, slide, accessories and parts, screw, guide pin, etc.