CNC rapid prototyping service is suitable for manufacturing small batch of products which is fewer than 100 pieces. It is a combination of CAD, CAM, and CNC technology that computer controls CNC machine to process a whole piece of material into the prototype product according to the three-dimensional data model on the computer. After the workpiece is clamped onto the CNC machine, digital control system controls the CNC machine to automatically finish all the processes on various surfaces of the workpiece. It also includes automatically changing the tool, changing the speed of machine tool spindle, etc. The processed surface of the workpiece can reach a pretty high quality. After our additional subsequent processes including polishing, burnishing, sandblasting, spray paint, silk screen, UV, plating and so on, the quality of workpiece is equal to or exceeding the similar workpiece manufactured by molding. Our CNC rapid prototyping service is especially suitable for manufacturing metal or plastic rapid prototyping in various industries including automobile, medical treatment, digital electronics, etc.

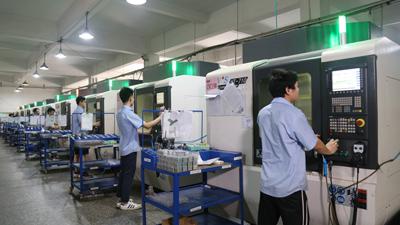

We are dedicated to providing high quality and high precision CNC machining service to meet your strictest needs of the product. We have advanced equipment including 41 sets of high speed 3-axis CNC machines, 4-axis CNC machines and 5-axis CNC machines. We also attach great importance to people development so we have experienced and well-trained engineer teams.

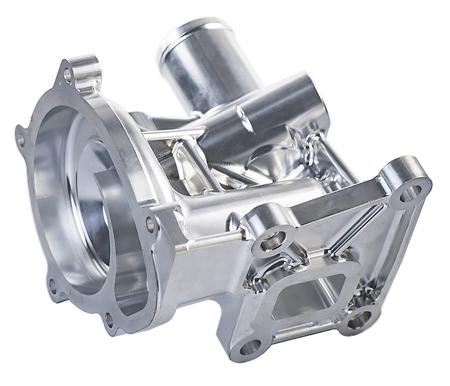

Advantages of CNC Machining- CNC machining can rapidly manufacture the parts with sculptured surface and complex form such as parts with groove, raised should, and hollow part.

- It supports fully automated production at night.

- CNC machining has higher processing efficiency than traditional machine tool cutting operations. It can rapidly create prototype and mold.

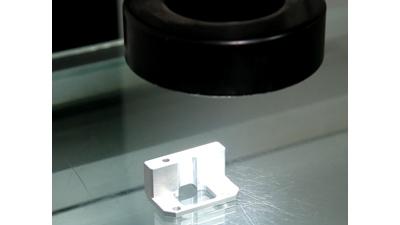

- CNC machining provides a high machining accuracy within ±0.025mm.

- It can process a wide scope of materials including ABS, POM, PMMA, PA, PC, PP, bakelite, aluminum alloy, magnesium alloy, zinc alloy, copper and other metallic materials. We will ensure the consistency of raw materials of the parts. Click here to learn more about material processing.

As a professional rapid prototype service provider, we use CAD conversion technique to realize the conversion of 2D to 3D. We can converse the sketch on paper to fully editable CAD file. Our design team is made up of experienced engineers. They know how to converse the sketch on paper or image files to multilayered electronic file formats, such as DWG, DXF. They also know how to recovery and reconstruct the design from damaged 2D files. Our engineers use various design software to efficiently meet your requirements, including Magics, SolidWorks, 3Design-CAD, Rhinoceros, Matrix, Zbrush, etc.

CAM usually uses NC programming language or G-code to drive the CNC machine to manufacture the parts. We use a micro rapid prototyping system called Solidscape T76+ to rapidly create the high quality molds.

Prototype should be created rapidly to save the time of design phase. We have 41 sets of high speed CNC machine to ensure our processing speed. We check the raw materials and CNC tools after we get the program of the part. We check and clean the CNC machine to ensure it can produce qualified parts during the designated time so that we can insure our delivery time. Your order usually will be delivered in 3-7 working days (small batch production)

This is the scenes we using CNC machine to process parts for our clients. Testing for finished productsWe are certified by ISO9001:2015 and have various measuring methods to ensure the quality of our products. Our test laboratory is welcome to your visit. We see quality as the most important thing of our company. We have introduced a variety of test equipment to ensure the quality of rapid prototyping. In the future we plan on investing even more to introduce higher precision and higher performance equipment to provide higher quality products.