- Home

- Rapid Prototyping Service

- CNC Milling

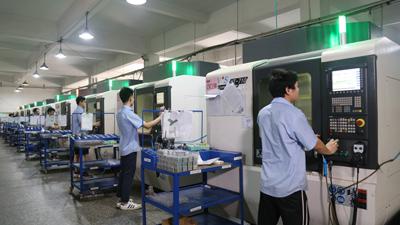

In recent years, we have consistently updated our equipment and procedures in order to offer the best possible prototyping services via CNC milling. Our CNC milling service is capable of achieving a strict geometric tolerance, optimizing product appearance and quality, and shortens the production cycle in order to achieve rapid prototyping and limited production.

What Is CNC Milling?Milling is a machining process that uses rotary cutters to remove material through the advancement of the cutter into a workpiece. CNC milling uses a CNC device to operate, and is used to mill components on different scales- from small, single pieces, to large, heavy combinations.

CNC Turning and MillingThere’s a tight relationship between turning and milling, which means that nearly every prototype produced is processed by both turning and milling. We own and operate qualified precise CNC machining devices, including a 3 and 5 axis milling machine to carry out turning and milling, ensuring we can meet all of our customer requirements.

Why CNC Milling? CNC milling works on various metals and plastics.

Via different tools, CNC milling is able to create pieces in nearly any 2D/3D shapes and various sizes and features.

CNC milling is highly accurate with a strict size tolerance, making it ideal for rapid prototyping.

CNC milling is highly efficient and cost efficient.

Various materials for various industries, from metal to plastic, such as aluminum, brass, stainless steel, ABS, PC, nylon, POM, PEEK, and more.

Our CapabilityWe’re equipped with more than 70 CNC devices, which allows us to fully meet your needs for precision and speed.

4 Axis and 5 Axis MachiningThe 5 axis CNC machine tool is capable of complex parts processing, and effectively increases our production efficiency and precision, allowing us to turn customer designs into reality, no matter how complex.