- Home

- Casting And Finishing Service

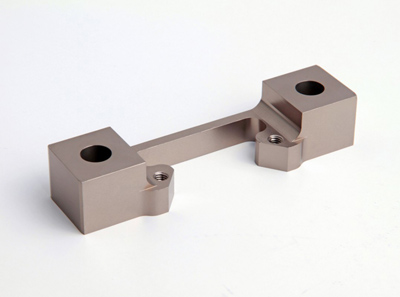

We provide a rapid casting service that is suitable for casting aluminum, alloy steel, carbon steel, etc. The most common procedure is to produce prototypes by investment casting, then process them by machining and surface treatment to get better performance.

For designing support, we provide CAD support to convert your draft or blueprint from 2D to 3D. We also provide CNC precise machining, finishing, surface treatment, checking, and certification service.

About Investment CastingInvestment casting (Lost Wax Casting/Precision Casting) is a procedure vastly applied for metal processing. Investment casting applies wax for a shell mold, and is suitable for producing parts that are of high precision with smoother surface than sand mold casting. Investment casting is usually applied for producing: industry machinery and equipment, valves, pump, injection engines, gas turbines, measuring instrument, aircraft parts, internal combustion engines, vehicles, food machinery, printing machinery, paper machinery, compressors, sewing machines, steam turbines, weapons, business machines, and other machine parts.

Investment casting parts are ensured with accuracy within 0.02mm, after die casting, the parts will be precisely processed with CNC machining. This procedure features significantly better speed than direct CNC processing.

Casting Parts can be optimized by various surface treatments, we provide finishing service including:- Brushing: Usually applied for surface brushing before coating and oxidation for aluminum or steel surface, to make better looking surface.

- Mirror Polishing: Able for processing ABS, PMMA, Aluminum, Brass, Stainless Steel, etc.

- Anodizing: Mainly applied for Aluminum 6061, Aluminum 6063.

- Blasting: Applied for metal or plastic surface matte treatment. Roughness is adjustable by switching sand type.

- Heat treatments

- Nitriding

- Carburizing

- Passivation.

- Powder Coat

- Painting