- Home

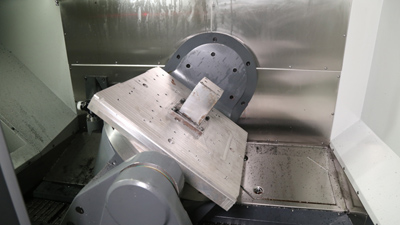

- CNC Machining Service

CNC machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and equipment. Our technology team has programmed our devices to optimize them processing timing, surface finishing and tolerance to meet your needs.

CNC machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and equipment. Our technology team has programmed our devices to optimize them processing timing, surface finishing and tolerance to meet your needs.

We apply CNC machining to produce not only products and prototypes but also molds, which might be applied for investment casting or die casting.

Milling is usually applied for processing axial symmetry parts with many features, such as holes, grooves, slots, and even 3D surface shapes.

Advantages of CNC Machining- Suitable for processing various materials, including stainless steel, carbon steel, nickel alloy, copper alloy, aluminum alloy, etc.

- High accuracy, repeatable processing.

- High efficiency, short production cycle, even 2-3 days only.

- Low up-front cost, cost-efficiency.

- Aluminum Alloy: 2024/5052/6061/6063/7075

- Copper Alloy: brass/bronze/beryllium copper/copper

- Stainless Steel: SUS303/SUS304/SUSU316/SUS420/SUS440c

- Metal: ±0.01mm

- Plastic: ±0.05mm

CNC machining is suitable for processing metal and plastic, such as aluminum alloy, stainless steel, copper alloy, ABS, PMMA, etc. Its products are similar in appearance and feel with mass produced ones. CNC machining is suitable for producing products with strict tolerance requirement, such as screw thread, threaded hole and precise plane combination.

We are equipped with tens of CNC 3/4/5-axis machining centers, for more information, please click here.